Cryogenic Pressure Relief Valves

RegO’s NR Series is designed especially for indoor applications (i.e. laboratories) where relief valve discharge noise is an issue. PRVs provide excellent flow characteristics with a 50% reduction in outlet noise related to valve relief.

- Packaged and cleaned for oxygen service per CGA G-4.1

- Bubble tight at 95% of set pressure

- 100% factory tested

- Repeatable performance

- Temperature range -320° to +165° F

B-19434B Serie

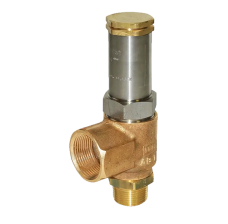

These relief valves are suitable for use with oxygen and non corrosive gases. The C-19434B series relief valves are designed for use in carbon dioxide service.

- Both designs permit the valve to open slightly to relieve moderately excessive pressure.

- When the pressure increases beyond a predetermined point, the valve opens to its full discharge capacity in order to quickly reduce excess pressure.

- Pipe-away adapter for venting gas to the outdoors is available.

- A.S.M.E. rated. NB Certified.

- B-19434-B Series are cleaned for use in oxygen per CGA G-4.1.

PRV 9400 Series

These relief valves are specifically designed for thermal safety relief applications and for use with cryogenic liquid containers.

- All valves are cleaned and packaged for oxygen service per CGA G-4.1.

- Bubble tight at 95% of set pressure.

- Easy to read color coded psig / bar labels.

- Adapters provide standard pipe thread connections for venting gas to the outdoors.

- Repeatable performance.

- 100% factory tested.

- Temperatures Range -320° to +165° F.

PRV 19430/29430 Series

These relief valves are designed for oxygen / other industrial gases and for cryogenic service. Apply on piping systems, liquid cylinders, or mini-bulk cryogenic containers where an ASME relief valve is desired.

- • A.S.M.E. rated, National Board Certified.

- • Bubble tight at 95% of set pressure.

- • Full flow at 110% at set pressure.

- • Repeatable performance.

- • 100% factory tested.

- • Temperatures Range -320° F to 165° F.

- • Cleaned and packaged for oxygen service per CGA G-4.1

AR Series

The ASME approved 90° relief valves AR Series, provide precise control set points which protect cryogenic vessels and piping systems for over-pressurization.

- High flow rates are approved by rigorous testing to ASME Code VIII.

- The ninety degree configuration provides relief of LNG gases directly avoiding flow through the spring.

- Bubble tight seat provides 100% shut off when reseating or static mode

- A variety of inlets and pressure settings assure adherence to application requirements.

- Temperature Range: -320°F (-196°C) to +165°F (+74°C)

- Cleaned for Liquid Oxygen Service per CGA G-4.1 • 100% Factory Tested.

RegO’s NR Series is designed especially for indoor applications (i.e. laboratories) where relief valve discharge noise is an issue. PRVs provide excellent flow characteristics with a 50% reduction in outlet noise related to valve relief.

- Packaged and cleaned for oxygen service per CGA G-4.1

- Bubble tight at 95% of set pressure

- 100% factory tested

- Repeatable performance

- Temperature range -320° to +165° F

B-19434B Serie

These relief valves are suitable for use with oxygen and non corrosive gases. The C-19434B series relief valves are designed for use in carbon dioxide service.

- Both designs permit the valve to open slightly to relieve moderately excessive pressure.

- When the pressure increases beyond a predetermined point, the valve opens to its full discharge capacity in order to quickly reduce excess pressure.

- Pipe-away adapter for venting gas to the outdoors is available.

- A.S.M.E. rated. NB Certified.

- B-19434-B Series are cleaned for use in oxygen per CGA G-4.1.

PRV 9400 Series

These relief valves are specifically designed for thermal safety relief applications and for use with cryogenic liquid containers.

- All valves are cleaned and packaged for oxygen service per CGA G-4.1.

- Bubble tight at 95% of set pressure.

- Easy to read color coded psig / bar labels.

- Adapters provide standard pipe thread connections for venting gas to the outdoors.

- Repeatable performance.

- 100% factory tested.

- Temperatures Range -320° to +165° F.

PRV 19430/29430 Series

These relief valves are designed for oxygen / other industrial gases and for cryogenic service. Apply on piping systems, liquid cylinders, or mini-bulk cryogenic containers where an ASME relief valve is desired.

- • A.S.M.E. rated, National Board Certified.

- • Bubble tight at 95% of set pressure.

- • Full flow at 110% at set pressure.

- • Repeatable performance.

- • 100% factory tested.

- • Temperatures Range -320° F to 165° F.

- • Cleaned and packaged for oxygen service per CGA G-4.1

AR Series

The ASME approved 90° relief valves AR Series, provide precise control set points which protect cryogenic vessels and piping systems for over-pressurization.

- High flow rates are approved by rigorous testing to ASME Code VIII.

- The ninety degree configuration provides relief of LNG gases directly avoiding flow through the spring.

- Bubble tight seat provides 100% shut off when reseating or static mode

- A variety of inlets and pressure settings assure adherence to application requirements.

- Temperature Range: -320°F (-196°C) to +165°F (+74°C)

- Cleaned for Liquid Oxygen Service per CGA G-4.1 • 100% Factory Tested.