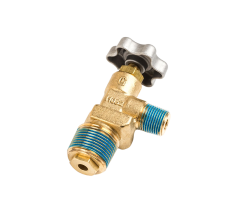

Cylinder Valves

We provide the compressed gas industry with high performing valves for a wide variety of applications. Our products are highly functional and compliant with industry standards.

We offer valves in the sub-categories mentioned below along with options for additional applications such as CGA 590 Industrial Air & Sulfer Hexafluoride, CGA 280 Medical Breathing Air, CGA 330 Non-Corrosive Gas, CGA 296 Industrial Gas Mixtures and many more. If you do not see your applications listed please do not hesitate to reach out to our team at sales@evergreenmidwest.com

Key Features & Benefits of Industrial Gas Valves:

- Industry standard compliance due to automated testing and assembly processes

- Tested for zero helium leakage

- Control and regulate pressure in threads located at top of valves -> help of a metal-to-metal seal below bonnet threads

- Internal components meet the most stringent valve performance standards in the international market

- Tapped for dip tube as required

- Durable and high pressure resistance due to strong forged-brass build

- Excellent flow characteristics due to pressure relief device coupled with tamper resistance and proper assembly

- Wide range of inlet and outlet thread configurations available for a broad spectrum of country, customer, and code specifications

- Reduced friction and low-torque operation due to direct-drive stem design with optimized O-ring (GV) or double O-ring (GVHM)

Shop By Cylinder Valves Type

We provide the compressed gas industry with high performing valves for a wide variety of applications. Our products are highly functional and compliant with industry standards.

We offer valves in the sub-categories mentioned below along with options for additional applications such as CGA 590 Industrial Air & Sulfer Hexafluoride, CGA 280 Medical Breathing Air, CGA 330 Non-Corrosive Gas, CGA 296 Industrial Gas Mixtures and many more. If you do not see your applications listed please do not hesitate to reach out to our team at sales@evergreenmidwest.com

Key Features & Benefits of Industrial Gas Valves:

- Industry standard compliance due to automated testing and assembly processes

- Tested for zero helium leakage

- Control and regulate pressure in threads located at top of valves -> help of a metal-to-metal seal below bonnet threads

- Internal components meet the most stringent valve performance standards in the international market

- Tapped for dip tube as required

- Durable and high pressure resistance due to strong forged-brass build

- Excellent flow characteristics due to pressure relief device coupled with tamper resistance and proper assembly

- Wide range of inlet and outlet thread configurations available for a broad spectrum of country, customer, and code specifications

- Reduced friction and low-torque operation due to direct-drive stem design with optimized O-ring (GV) or double O-ring (GVHM)